I admit it. I can't drive, walk or ride by a culvert without swiveling my neck, inspecting and visually evaluating the structure, judging condition, materials and construction and looking at the drainage to see how well, or if, it is performing its intended function.

I admit it. I can't drive, walk or ride by a culvert without swiveling my neck, inspecting and visually evaluating the structure, judging condition, materials and construction and looking at the drainage to see how well, or if, it is performing its intended function. I am particularly happy that for the first time in my lifetime I live on a lot that has a driveway culvert. It's a small pipe, a twelve incher, but plenty big enough to do the trick because the configuration of the land here in our little section of the foothills is such that the high side entry point will flow only in the event of biblical downpours (like Boulder, Colorado experienced last summer) because it drains no more than a 100 feet of frontage. The pipe ends have been damaged by lawn mower assaults, but the pipe remains clear, as we can ascertain when a neighborhood cat (or a skunk) passes straight through during its regular rodent stalking rounds.

My fascination with culverts comes from experience. We built culverts (no, somebody else didn't do it for us Dear President, we did it ourselves).

I was a sophomore in college working for my meals at the Gamma Phi Beta sorority house on Langdon Street in Madison Wisconsin, when I casually mentioned I would like to find a local job so I could stay in Madison that summer. The parents had moved to an apartment out in the boonies in the Chicago area. I wasn't partial to spending another isolated summer there while working a dreary factory job.

My job at the sorority was houseboy, which meant I did odd job clean, fix, sweep, shove, store and remove it work around the house, and interacted most days with the housemother, the maid and the cook on assignments. Whenever there was extra work I would take it up. The housemother was generous to promise me the princely sum of $2.50 per hour and ended up paying me more like $4.00 or $5.00 an hour. When she went down to Florida for Christmas break she would pay me $10.00 a night to house sit (when the Sigma Chi's broke in one night after a drinking binge you would have thought they saw a ghost when I walked out of the kitchen door).

|

| Gamma Phi Beta sorority house, 270 Langdon Street, Madison, WI. Outside view same as 40 years past. |

Wisconsin Culvert's top customers were town and county road and maintenance departments and private developers and, secondarily, the state of Wisconsin and farmers. The front office was the Johnson brothers plus a secretary. In the shop there were 8 permanent, full time employees, plus up to three university students in the summer. Sales peaked in the summer, but ground to a halt in the winter when the soil was too muddy or frozen to be worked. The permanent crew built inventories to the sky in the winter, but by the time I showed up in late May, sections of stacked and completed pipe were beginning to thin out.

Besides culverts, Wisconsin Culvert Company had a going business in farm pond dams (we called them dams but they were actually drains that siphoned off excess water once water rose above a specified level) and hay wagon covers, and would give a go at building anything transportable on a semi flat bed trailer that could be constructed using corrugated steel sheets, angle irons, arc welds, rivets and/or nuts or bolts. I recall a project fabricating rest stop restroom dividers from heavy corrugated steel bolted on angle irons, designed in hopes of thwarting the most motivated vandals. Back in the day, Wisconsin Culvert even fabricated nuclear fallout shelters (see below) to protects households from the impact and residue of atomic blasts.

|

| Fallout shelter display ad, Wisconsin State Journal, November 5, 1961 |

|

| Vintage Wisconsin Culvert Company notepad with nail file and comb. Note phone number AL 7-2593. |

|

| Oshkosh Daily Northwestern May 30, 1964 |

Sooner or later most of my co-workers took me privately aside, and encouraged me to continue my education, lest I not end up just like them, in a dirty, dangerous, and tiring dead end job. A couple of them had dropped out of the university in favor of a regular pay check. I appreciated their advice and friendship and resolved to visit a time or two during the school year to let the guys know I was thinking of them. When I stuck my head in they'd chirp before I could say a word, saying uh oh, here he comes, dropped out, looking for mercy and begging for work. They got in enough digs that they were happy to see me even though my visit kind of reminded them they were stuck in a rut.

In the front building we constructed standard 15, 18, 24, 36, 48 and 72 inch circular pipe. Any larger circular or large arched pipe we built in the back building that had more powerful equipment, higher clearances and a raised platform. Anything smaller than 15 inches we stocked as spiral welded pipe from other suppliers.

|

| Riveted corrugated culvert pipe. |

One work station was staffed by red headed brothers Rodney and Ron, who specialized in turning out high volumes of the smaller pipe. The other work station was operated by Tom and Chris who specialized in building the larger, more technically demanding 48 and 72 inch pipe, though either team could produce all sizes, depending on demand. Each station had a pit that was opened up to give clearance for large pipe, while staying covered and closed for small pipe construction.

| Input material, corrugated metal sheets. |

In the summer the two most senior employees, Bill and Jim, were constantly on the road, driving semis to make deliveries. Though they preferred to make up their own loads, we had extra trailers in the yard so loads could be made out when they were still on the road. Bill as the eldest with the most seniority got the most distant loads (some weeks I wouldn't see him) which normally meant he was on the road by 5 or 6 in the morning, not returning to the yard until after the shop was closed. He racked up incredible overtime, as did Jim here and there. Tom lived for the days when we needed a third truck on the road so he could escape from the monotony of continuously building three feet sections of pipe.

I did not know it at the time, but a couple decades previous, it turns out that Bill had been involved in a tragic incident that killed a four-year old girl.

+24+June+1955.jpg) |

| The Winona Daily News, June 24, 1955 |

|

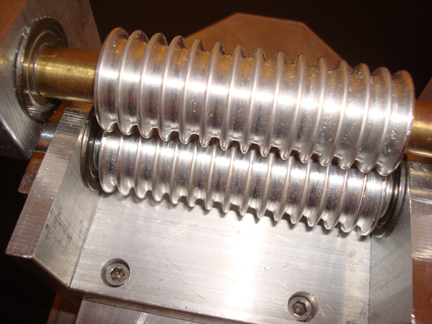

| Guts of a metal roll forming machine, the sharpness of curve determined by distance between rollers. |

At some point, Wisconsin Culvert Company had been a 6-day a week operation, working full days Monday through Friday and a partial day on Saturday. At the request of the employees it transitioned to a 9-hour day, 5-day a week operation, which I thought great because that guaranteed 5-hours a week of time and one-half overtime, plus weekends off. We worked our tails off all summer long. I understood the pace of work was more relaxed in the winter months.

Work started at 7:00 am, which meant I got up around 6:30 am in my room on Langdon Street, left for work around 6:45, rode my bike uphill for a couple blocks past the Wisconsin State Capitol and then tore ass downhill for a couple of miles down to Ingersoll Street on the east side of Madison, where Wisconsin Culvert was located on a pie shaped lot along a rail spur. On the way home, my bike ride was in the heat of the late afternoon and uphill most of the way. I'd be dragging.

Sometimes I'd have a summer meal job set up for the evening, other times I'd get out my electric frying pan and whip up tuna cheese melt or some other delicacy and yet other times I would go out with the guys, almost invariably to all you can eat specials. There was a pizza joint on the outskirts of town that had an all you can eat night. There was another restaurant that had an all you can eat fried chicken night. Occasionally I'd catch a cheese Plazaburger. The best deal of all was the old Madison Inn on Capitol Square whose restaurant had a delectable, melt in your mouth, all you can eat fish fry (apple sauce, veggies, rolls and french fries as well) on Friday nights, which we were sure to scrub up for and catch. We tipped well and ate well. The help loved us.

|

| The Capital Times, July 6, 1960 Wisconsin Culvert tar vat overheats. |

When I first worked at Wisconsin Culvert Company I was a helper. Up, down, higher, lower, hold this bolt, turn this wrench, grab here and let go there, and operate this saw (sawing through steel is a great way to burn holes in your clothes) were orders I responded to. I would unload rolled sections from the roller to help Bob. I'd fabricate hay wagon covers. I would help the boss on his forays out to the pipe press or the tar shack. And I would spot and chain up loads and pull chains off unloads.

|

| Schematic of large arch pipe construction, built in the rear shop at Wisconsin Culvert. |

Though we had ear protection and were told to wear it, the muffs were quickly discarded when we learned they made it impossible for Mr. Inside (air wrenching the bolt) and Mr. Outside (attaching the washer and nut to the spinning bolt) to reliably communicate with each other, with frequently bloody results. It was an environment of slivers and shards of steel each trying incessantly to find its way under your skin and into your flesh.

|

| Large arch pipe after construction and prior to installation. |

By then I had pieced together the material costs that went into our pipes, and learned that the work orders included sales prices. By my calculation the gross margin on big pipe (labor and materials) was on the order of 500 to 700 percent. This was an incredibly profitable business that paid me better than I had ever been paid before.

This was back in the days of high marginal tax rates that a lot of big government advocates and progressives look back fondly on. But that was only half the story. The Johnson brothers who owned Wisconsin Culvert each drove Cadillac company cars (as did their secretary) for business and personal use. They tooled around in their restored Model T (restored by staff) with Wisconsin Culvert's logo painted on the side door. They would take off in their private four seat plane for pleasure and to entertain clients.

|

| Janesville Daily Gazette, December 14, 1967 |

Daily 3 hour gourmet lunches, nighttime dining and afternoons at the country club were the norm. All of this done on the company dime, plus we helped to build, expand or maintain their personal homes.

Under the laws of the day, the Johnsons didn't pay a dime of taxes for any of the perks or in-kind income, something that would get them an appointment with a federal prosecutor in today's tax regime. I would wager that their tax rate based on actual income was less then than it would be today.

|

| Old Wisconsin Culvert site operating components mapped on today's green field, 201 S Ingersoll St. Madison, WI. |

|

| Spiral welded culvert pipe |

The last time I sat down with the Johnson brothers we talked about my future plans going to law school. I mentioned I might want to go into Antitrust law. They blanched and suggested that might not be an honorable pursuit. Now that (below) we can see they were repeatedly in hot water for price fixing, I can understand why.

+30+Nov+1948.jpg) |

| The Winona Republican Herald, November 30, 1948 |

|

| The Post Crescent (Appleton Wisc.), April 11, 1962 |

|

| Janesville Daily Gazette, February 24, 1961 |

And here are a couple more Wisconsin Culvert clippings.

|

| The Capital Times, July 2, 1939 |

|

| Burglary at Wisconsin Culvert. Hitler tightens his grip on Poland, The Capital Times. October 24, 1939 |

I've placed miles of culverts, including precast, poured in place and corrugated pipe.

ReplyDeleteIn my neck of the woods, corrugated metal pipes will eventually rust away, unless they're made of aluminum, which is usually too expensive. They're never used on state, or municipal projects, except in unique circumstances.

Concrete is the preferred choice in culverts. They're heavy, require specialized equipment and the installer better have a damned good pipelayer in the hole. Poor grading can lead to offset joints, which will eventually leak and cause problems.

What a truly beautiful story.

ReplyDeleteI enjoyed your story- I too, have oldtimer's disease. Those were the good times, back then.

ReplyDeleteDawn Marie, the little 4 year old girl who was killed by a culvert, has no one to tend to her grave, since her parents and sister have died- please, someone, keep her gravestone open and clean.

https://www.findagrave.com/cgi-bin/fg.cgi?page=gr&GSln=dale&GSfn=dawn&GSby=1951&GSbyrel=in&GSdy=1955&GSdyrel=in&GSst=51&GScntry=4&GSob=n&GRid=97811308&df=all&